RockTech USA • 4164 W Industrial Loop • Coeur d’Alene • ID • 83815 • Phone +1 208 765-4231 • Fax +1 208 765-8248

Website designed by DBA Graphix 2011

Devico SURVEY INSTRUMENTS

Devico delivers a complete set of products for directional core drilling and borehole surveying. We help the mining, exploration, tunnelling and petroleum industry to improve operations, achieve greater profitability and complete boreholes more effectively.

Directional core barrel

Full range of magnetic and non-magnetic surveying tools

A continuous core orientation system

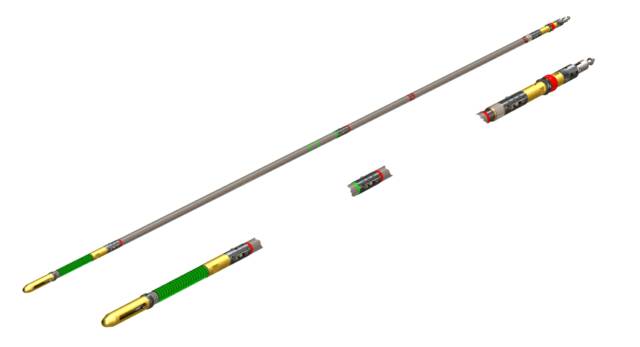

DeviDrill™ -

Directional core barrel

The DeviDrill is a steerable wireline core barrel. The design of the N-size tool was introduced in 2001. Today it is successfully applied in various projects all over the world, from geotechnical investigations to the mining industry. The DeviDrill reduces the cost of exploration drilling programs by hitting targets quicker and more accurately than with traditional core drilling methods. By making multiple branches from a mother-hole it dramatically reduces both the time spent and the cost, and, in addition, you get the geological information from wherever you want. No time is lost on moving the drill rig, drilling through the overburden, and drilling further down to where you almost were with your previous hole.

Time and money saver

Clients have reported time and cost savings of up to 80 percent in projects where the DeviDrill was used. A satisfied geologist stated: “Devico forced the hole down in inclination, and the 1000 meter deep hole switched from total failure to great success.”

The DeviDrill uses a normal drill string and is fully compatible with the NQ wireline system. There is no need for additional water pumps, drill strings, or survey instruments. Devico’s survey tools are a fully integrated part of the tool, as they stay on board and measure while drilling.

Coring during steering provides a complete record of the geology. It leaves nothing in the hole - except a bend. The curvature or dogleg can be adjusted from completely straight to more than 20 deg/30 meters. However, the recommended curvature from the drill rod manufacturer is 9 deg/30 meters, as any greater deviations will result in extensive wear on the drill rods.

DeviTool™ -

Full range of magnetic and non-magnetic surveying tools

The small, rugged, and powerful tool that can withstand the highest pressures and the most reckless person.

Non- magnetic electronic multishot for surveying inside casings and drill strings

If you know how to run your inner tube, you know how to run your DeviFlex. It is THAT easy.

DeviFlex is a non- magnetic electronic multishot for surveying inside casings and drill strings by simply using the wireline system. Magnetic disturbances will not influence the tool at all and it is supposed to be simple to use. Just pump the tool into the hole and pull it out in given intervals. No adjustments are necessary

The DeviFlex tool consists of two independent measuring systems. Three accelerometers and four strain gauges are used to calculate inclination and change in azimuth. In addition, the DeviFlex records and stores gravity vector, temperature, and battery capacity.

The DeviCore is a continuous core orientation system and a high-accuracy instrument that registers the orientation of the core and inclination of the hole.

A shorter simplified version of the DeviTool Standard

If you know what you need, it is unnecessary to pay for additional features.

The DeviDip electronic multishot is a simplified version of the DeviTool Standard. It has the same rugged design, but the length of the tool is shorter. The DeviDip can stay onboard core barrels while drilling. Because of that and its length, the DeviDip is a good choice for core orientation systems.

The DeviDip uses three high-accuracy accelerometers. The tool measures inclination, toolface, gravity vector, and temperature and battery status. Time intervals can be set from 5 seconds and up.

The DeviDip has been used for orientation of tools at inclinations less than 1.5 degrees from the vertical with perfect results. The tool is used as a steering tool for the DeviDrill, but can also be used together with other instruments, such as wedges and downhole motors.

The DeviDip communicates with a PDA through a Bluetooth modem. The results can be viewed on the PDA screen in field once the data is downloaded from the tool. The data can thereafter be further processed in DeviSoft, analyzed, plotted and reported to the client.

The DeviDip has been used for orientation of tools at inclinations less than 1.5 degrees from the vertical with perfect results. The tool is used as a steering tool for the DeviDrill, but can also be used together with other instruments, such as wedges and downhole motors.

Devico™ -

Accessories

Running gear

In order to get most out of your DeviTool Standard, PeeWee or DeviDip you need a running gear. The Devico running gear can handle pressure up to 450 bars and follows industry standards.

The running gear fits most 30 mm diameter survey tools on the market. They are available in 36 and 38 mm diameter.

Weight: 7.5 kg / 8.0 kg

Length: 2020 mm/ 2020 mm

Diameter: 36.4 mm / 38 mm

Pressure: 300 bar/ 450 bar.

Extra batteries for Dell PDA.

Get more surveys out of your Dell PDA. Upgrade the PDA with longer lasting batteries.

Nomad PDA

Do you need a more robust PDA? Upgrade your survey kit with a Nomad PDA. The Nomad PDA is waterproof and stands fall from at least 1.5 meters. A serial cable is also included in the upgrade package. The advantages are shorter download time and less charging of batteries.

The PeeWee is a miniature electronic multishot based on the same reliable technology as the DeviTool Standard. It comes with an integrated running gear and is ready to go as is, regardless of whether you want to survey open cased boreholes, grout curtains, blast holes, etc.

The PeeWee uses three high-accuracy magnetometers and accelerometers. It records inclination, azimuth, toolface, temperature, gravity vector, magnetic field vector, magnetic dip angle, and battery status. Time intervals can be set from 5 seconds and up.

The tool can handle pressures up to 500 bars. It is small enough (diameter 30

mm) to survey throughout the DeviDrill bit or an AQ bit. This means your core barrel can stay inside the hole while the survey is performed in front of the bit.

PeeWee

The PeeWee communicates wirelessly with a PDA and the results can be viewed on the PDA screen in field once the data is downloaded from the tool. The data can thereafter be further processed in DeviSoft, analyzed, plotted and reported to the client.

DeviTool™ -

Full range of magnetic and non-magnetic surveying tools

It is of vital importance to know where your borehole goes, whether you are in the mining industry, doing geotechnical investigations, or preparing blast holes.

Standard

DeviTool Standard is an electronic multishot survey instrument. Its rugged design makes it tough enough to stay inside the Devidrill core barrel while drilling and still provide reliable results.

The DeviTool Standard uses three high-accuracy magnetometers and accelerometers. The tool records inclination, azimuth, toolface, gravity vector, magnetic field vector, and magnetic dip angle, as well as temperature and battery status. Time intervals can be set from 5 seconds and up.

The DeviTool performs all-angle surveys with high precision. With its 30 mm diameter it fits inside all standard running gears available on the market. It is delivered in a transport box, and is easy to carry around. The tool has been successfully used in a broad variety of applications all over the world.

The DeviTool communicates wirelessly with a PDA and the results can be viewed on the PDA screen in field once the data is downloaded from the tool. The data can thereafter be further processed in DeviSoft, analyzed, plotted and reported to the client.

Non- magnetic electronic multishot for surveying inside casings and drill strings

A continuous core orientation system

Electronic multishot survey instrument

Miniature electronic multishot

A shorter simplified version of the DeviTool Standard

Running gear, batteries and PDS's

Devico

How it works

The principle behind the tool is a drive shaft running through a bushing offset from the centre line of the tool. Expanding pads operated by a differential pressure is keeping the DeviDrill in a fixed toolface while drilling in a curve. The inner assembly carries an inner tube collecting the core, a muleshole system, and an instrument barrel with the survey tool recording inclination and tool orientation. Data is stored inside the tool and downloaded wirelessly to a PDA after each run.

There is no need to trip drill rods in and out of the hole during directional coring, surveying and orientation, as this is all wireline operated.

The DeviDrill has been proved to work well in both igneous and sedimentary rocks. Over time, Devico has gained much experience in how the DeviDrill behaves under different conditions, and possesses valuable information about directional planning and drilling.

The DeviFlex fits casings and drill strings from B-size and up to P-size. You need one instrument and a set of sleeves with various wheel sizes to adjust for different hole dimensions. The tool has been proven to work in horizontal as well as vertical holes.

The DeviFlex communicates with a PDA through a Bluetooth modem. The results can be viewed on the PDA screen in field once the data is downloaded from the tool. The data can thereafter be further processed in DeviSoft, analyzed, plotted and reported to the client.

- No interruption of the drilling cycle, i.e.

- Continuous core orientation

- Cost effective

- Regular readings

- Accurate orientations and inclination

- Effective in a broad range of ground types and core breaks

- Can be used in up or down boreholes as well as in horizontal boreholes

- Digital data recorded for use in analyses at a later time

Using Devico’s CCO system offers the following advantages:

Put the DeviCore probe into the top section of your inner tubes with inner diameter from 37 mm and up, and attach the custom made core scratchers behind your core lifter case and you can start drilling.

The core lifter case has tungsten blades that scratch the entire core entering the inner tube during drilling. The positions of the blades are fixed with respect to the reference position of the probe. During drilling the system measures the core orientation (scratches on the core), as well as the borehole inclination.

Data from the core orientation can be used for core analyses in order to accurately determine the dip and strike of bedding, foliation, cleavage, healed or broken joints, contacts, shears, etc. Oriented petrographic thin sections for use in further studies may also be obtained from the oriented core.